Why Coatings are Important

Billions of dollars are spent annually on the corrosion protection of products and infrastructure through the application of coatings. New, as well as existing technologies, require extensive analysis to ensure specific performance criteria are met. Decorative and protective properties of coatings are evaluated utilizing standardized and custom test plans to fit both the client’s needs and their budget.

Most coating performance issues are related to improper surface preparation and/or application, wrong choice of coating or exposure to an unanticipated environment. Quality control testing prior to placing the coating in service can help identify problems and avoid premature failures.

Common Tests Include:

- Mandrel Bend

- Variable Impact

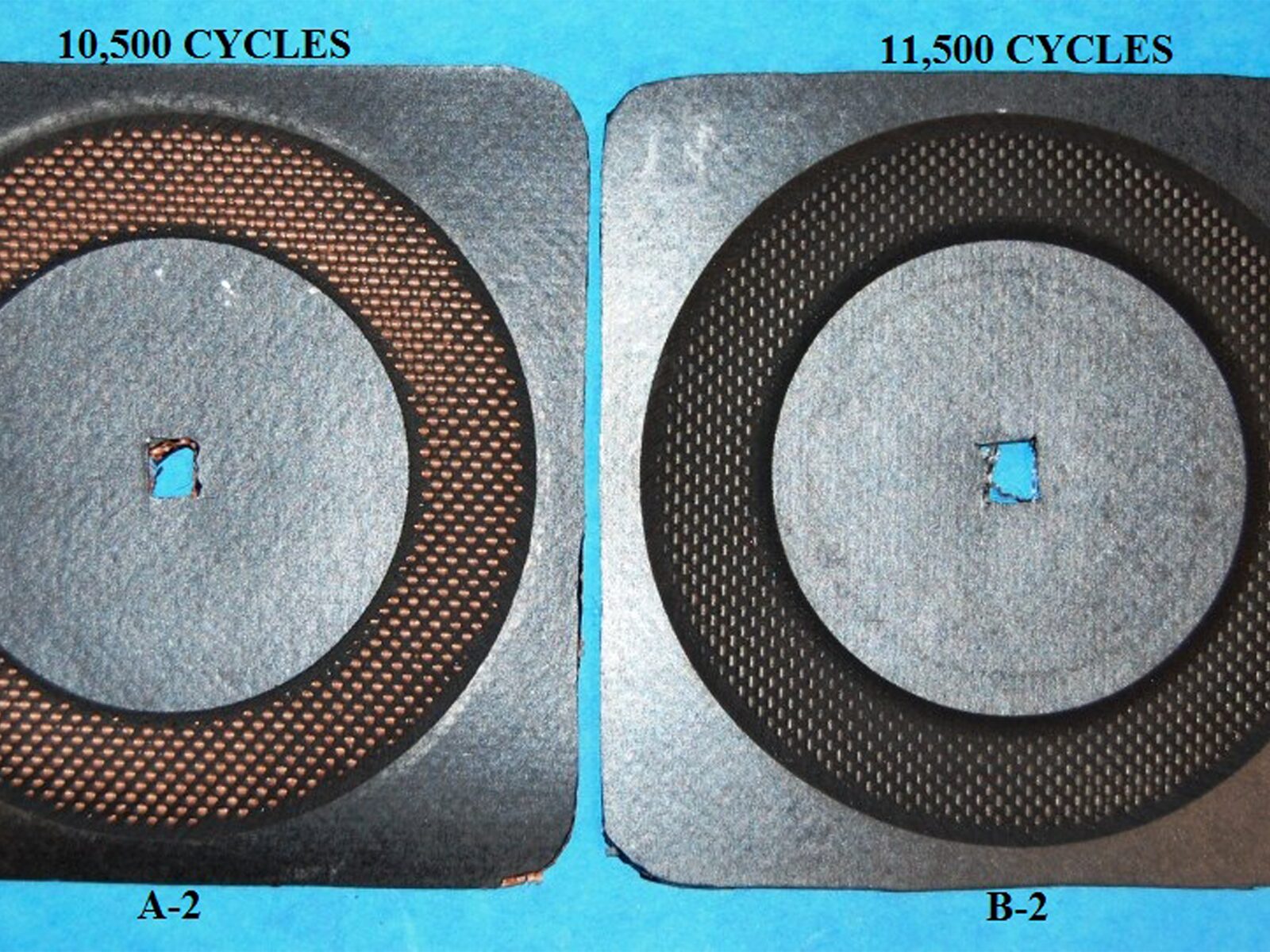

- Taber Abrasion

- Scratch and Mar Resistance

- Coating Thickness

- Coating Weight

- Solvent Resistance

- Weathering

- Freeze/Thaw

- Color and Gloss

- Abrasion

- Adhesion

- Chemical Resistance

- Flexibility

Typical Specifications

The ATS testing experts can follow procedures and specifications from a variety of industry and international authorities, including:

- IEC Standards

- ASTM Standards

- Military Standards

- Automotive Standards

About ATS

ATS strives to provide testing, inspection, and certification solutions for a wide range of industries, from automotive to manufacturing. We are an ISO 9001:2015-registered company with several ISO/IEC 17025:2017-accredited labs for testing and calibrations.